Durable, versatile, low cost, abrasion and chemically resistant plastic material

HDPE (high-density polyethylene) is available in sheet and rod for applications that require greater strength and stiffness than LDPE (low-density polyethylene). It is easy to fabricate and weld using thermoplastic welding equipment and is an excellent choice for fabricated water tanks and chemical tanks.

HDPE is also available in a variety of additional grades for applications including FDA compliant for cutting boards, UV stabilized and woodgrain textured for outdoor environments, orthotic and prosthetic for addition support, and antimicrobial for medical facilities. These materials are easy to fabricate using standard machining methods and common woodworking tools.

HDPE IS WIDELY USED FOR:

- Chemical tanks

- Cutting boards for food preparation

- Water pipe flanges (HDPE pipe grade)

- Outdoor and indoor playground systems

- Marine construction (pile guards, bumpers,

anti-skid surfaces) - Orthotics and prosthetics – AFOs, KAFOs

- Light duty tank, chute and bin linings

- Outdoor cabinetry and furniture

PERFORMANCE CHARACTERISTICS:

- Easy to weld using thermoplastic welding equipment

- Low moisture absorption

- Excellent surface for food preparation

- Good chemical and corrosion resistance

- Easy to fabricate and machine

- Low weight

COMMON BRANDS:

- Polystone® G

- Sanatec®

- Orthoform®

STANDARD SIZES

| INDUSTRIAL SHEET | Dimensions: 48 in x 96 in – 60 in x 120 in Thickness: 0.062 in – 4 in |

| O&P SHEET | Dimensions: 24 in x 48 in – 48 in x 96 in Thickness: 0.0312 in – 0.250 in |

| ROD | Outside Diameter: 0.250 in – 14 in |

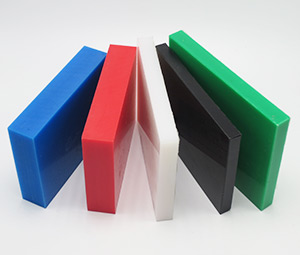

| COLOR | Industrial: Natural, Black, Red, Yellow, Green, Beige, Blue, Polar White, Mercury Gray, Seafoam, Sand Shade, Whitewash, Teak, Weatherwood, Dark Ash, Mahogany, Sunshade, Dolphin Gray, White/White O&P: Natural Engravable: Blue/White/Blue, White/Red/White, Black/White/Black, White/Black/White, Beige/Green/Beige, Blue/Yellow/Blue, and many more |

| TEXTURE, SURFACE, PATTERN | Matte/Matte, Smooth, Woodgrain |

| Grade | FDA Compliant, UV Resistant, Cutting Board, Marineboard, Playground Board, Multi-Color Engravable, Enhanced stiffness, Pipe Grade |

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes and colors available upon request.

TYPICAL PROPERTIES OF HDPE

| UNITS | ASTM TEST | HDPE | |

|---|---|---|---|

| Tensile strength | psi | D638 | 4,000 |

| Flexural modulus | psi | D790 | 200,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.3 |

| Heat deflection temperature @ 264 psi | °F | D648 | 172 |

| Maximum continuous service temperature in air | °F | – | |

| Water absorption (immersion 24 hours) | % | D570 | 0.10 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 7.0 |

Values may vary according to brand name. Please ask your Curbell Plastics representative for more specific information about an individual brand.

POPULAR PLASTIC MATERIAL COMPARISONS:

- HDPE vs. UHMW — Both are abrasion resistant, but which is right for your specific application?

- HDPE vs. LDPE — One is more rigid while the other is more flexible, but which is right for your specific application