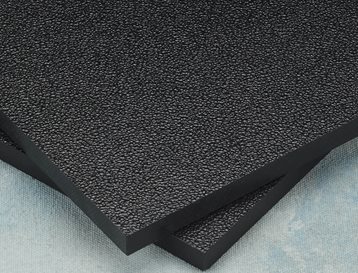

Outstanding impact-resistant low-cost plastic, easy to machine and thermoform

ABS is a low-cost plastic material with outstanding impact resistance, machinability, and thermoforming characteristics. It is an excellent choice for machine housings, retail store fixtures, and point-of-purchase displays when impact resistance or durability is required.

ABS plastic is available in general purpose, machine grade, fire-rated, UV resistant, orthotic grade, FDA compliant grade, and scratch-resistant grades in a variety of textures and colors.

ABS IS WIDELY USED FOR:

- Machine housings, guards, and covers

- Instrument panels

- Models and prototypes

- Point-of-purchase displays

- Storage cases and display bases

- Thermoformed displays, trays, and tote bins

PERFORMANCE CHARACTERISTICS:

- Outstanding impact resistance

- Easy to thermoform

- Easy to machine

- Easy to bond with adhesives

- Strong and stiff

- Low cost

COMMON BRANDS:

- Royalite®

- Polystone®

- TECARAN™

STANDARD SIZES

| SHEET | Dimensions: 12 in x 12 in – 48 in x 96 in Thickness: 0.060 in – 4 in |

| ROD | Outside Diameter: 0.250 in – 6 in |

| COLOR | Sheet: Natural, White, Off White, Black, Beige, Dark Gray, Light Gray, Red Rod: Natural, Black |

| TEXTURE, SURFACE, PATTERN | Level Haircell, Smooth / Smooth, Haircell 1 Side |

| GRADES | General Purpose, Fire-Rated, Machine Grade, UV Resistant, Scratch Resistant |

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes and colors available upon request.

TYPICAL PROPERTIES OF ABS

| UNITS | ASTM TEST | ABS | |

| Tensile strength | psi | D638 | 4,100 |

| Flexural modulus | psi | D790 | 304,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 7.7 |

| Heat deflection temperature @ 264 psi | °F | D648 | 177 |

| Maximum continuous service temperature in air | °F | 160 | |

| Water absorption (immersion 24 hours) | % | D570 | 0.30 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 5.6 |